Ties

Today composite ties are broadly used in sandwich panels. They connect the outer layer and the inner wall through an insulant layer.

According to cl. 6. 31 of SNiP II-22-81, ties shall be made of corrosion resistant or corrosion protected steels, as well as polymeric materials. We use composites, namely basalt-plastic and glass fiber as polymeric material.

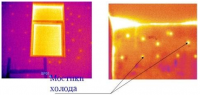

One of the ties’ most important properties is their thermal conductivity. It may be attributed to the fact that due to climatic conditions in Russia, the EPB issue is one of the most acute problems in our country. It is essential that ties have lowest possible thermal conductivity. It enables to avoid formation of the so-called “cold bridges” being the reason for heat loss and condensate formation in the walls.

Look at the heat image:

Structure

A great many of orange dots is cold bridges formed by steel ties. As practice shows, substitution of metal ties with composite ones reduced heat loss by 34%, due to which considerable saving on building heating is achieved.

Tie structure

Ties are round section rods made of basalt-plastic of glass fiber and covered with quartz sand. The sand is applied during reinforcement hardening in a furnace. That is why our products ensure a very good concrete adhesion, and have additional protection from the corrosive effect of alkaline concrete medium.

Tie installation

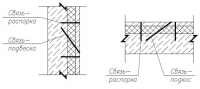

For connection of concrete layers in sandwich panels three types of ties are used — crossbars, suspension rods and braces. The joint use of cross bars and suspension rods ensures sufficient rigidity in the vertical plane, and crossbars and braces provide for horizontal rigidity.

Ties location and their number are determined by the project. According to the standards, the depth of tie mounting into panel inner layer shall be 100 mm and the ties shall penetrate into the outer layer throughout its thickness. The distance from the panel edge shall be at least 100 mm, but not more than 250 mm.

The time of heat insulation laying and lower panel concreting is of a great importance here.

First of all one need to install cross bars at the right angle to the heat insulation layer, and then after checking reinforcement mesh laying, rackers shall be installed. Vibratory compacting and heat treatment contribute to proper tie adhesion.

For panel production it is advisable to use basalt-plastic ties with 7.5 mm core diameter and 8 mm outer diameter (with the sand layer). For calculation of the number of ties per panel and their length panel parameters are needed.

Best regards, Malashkin Alexey

On cooperation issues please call: +7 (8342) 23-11-44 ;